Since 1984, we have been offering perfectly thoughtout

solutions for every form of workpiece clamping

in a wide variety of industries and for all applications.

With our systems, we now achieve a measurable optimization

of industrial manufacturing processes.

Due to high precision, quality and system competence, throughput times are minimized, time and money are saved and process complexity is reduced when clamping devices are used.

How does that work? We rely on three idealistic success factors. Clamping technology can be the key to assured product quality.

Decades of Expertise

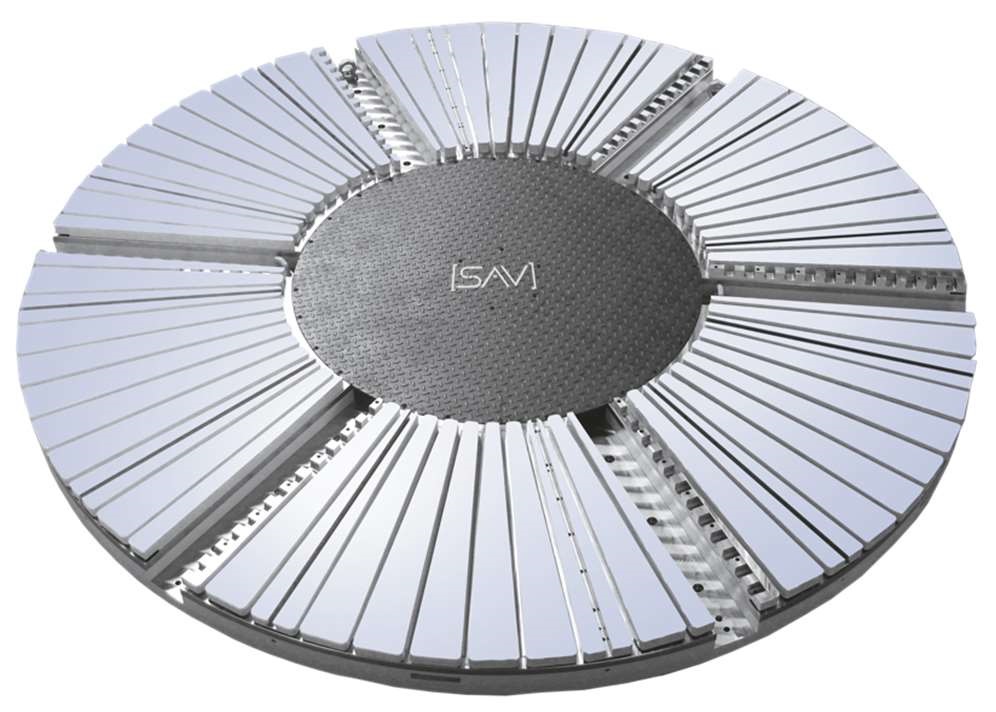

Founded in 1984 and now a pioneer in clamping technology, SAV delivers precision-engineered solutions that measurably optimize industrial machining processes with reduced lead times, lower costs, and streamlined complexity.

Customer-Centric Innovation

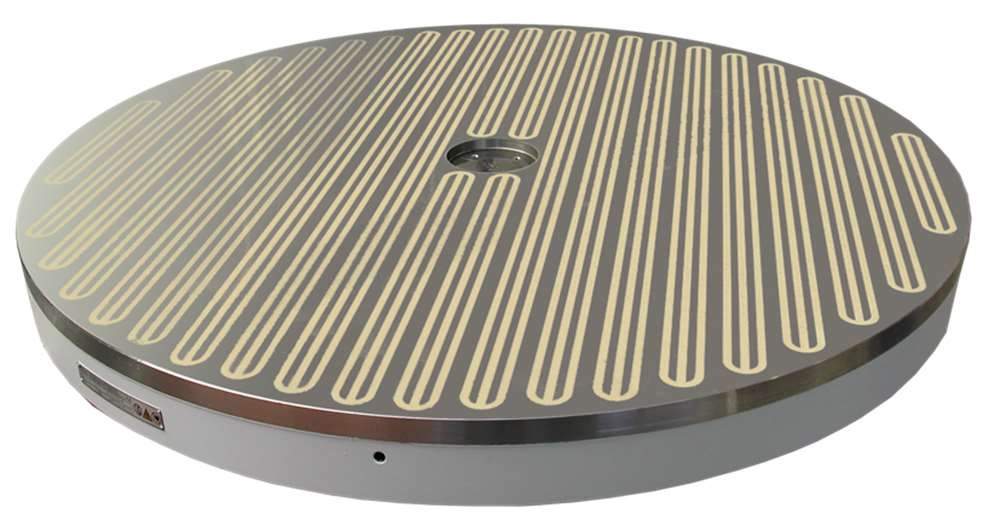

SAV’s approach emphasizes close collaboration—whether with standard or custom magnetic, electro-magnetic, or hybrid fixtures—to tailor solutions that precisely fit each unique machining challenge.

Unmatched Quality & Availability

Their product range includes a variety of permanent, electro-, and electro-permanent magnetic clamping systems, all designed for high durability, performance, and ready usability.

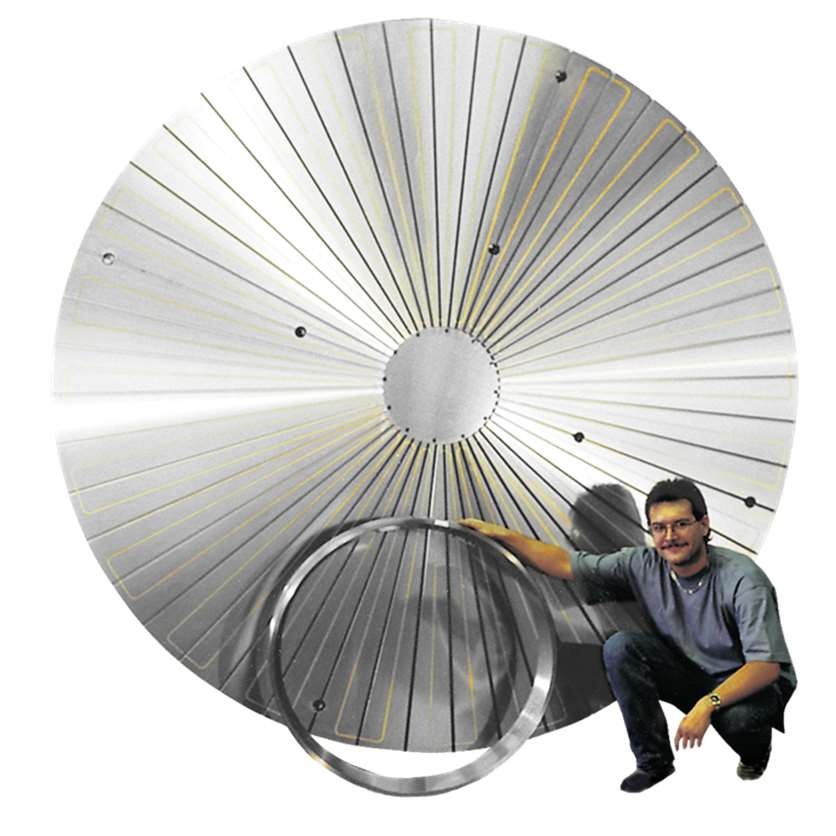

Sophisticated Custom Solutions

SAV engineers bespoke fixtures—from special magnetic workholding to rotary chucks, for machining centers or dedicated special-purpose machines—designed for quality, longevity, and 24/7 operational reliability.

High Impact Across Industries

Serving sectors such as automotive, aerospace, renewable energy, rail, precision components, and machine tool manufacturing, SAV combines deep process know-how with cutting-edge technology to consistently deliver results.

Guided by Passion, People, Power

Anchoring its brand are three ideals: Power in capability and results, People in skilled craftsmanship and client focus, and Passion in continuous innovation.